Two Roads, Two Designs: Tailoring EV and Hybrid Systems for Powersports and Automotive Excellence

Electrification is no longer just a buzzword; it powers a major share of the mobility market across industries. But as EVs and hybrid electric vehicles (HEVs) reshape automotive landscapes, another realm is also undergoing a transformation—powersports. From off-road adventurers to utility task vehicles (UTVs), the integration of electric and hybrid systems is redefining performance benchmarks for these rugged machines.

While both powersports and automotive vehicles may use similar technologies, they operate in completely different contexts with unique demands. This blog unpacks the key similarities and differences, offering insights into battery chemistry, energy optimization, and system design tailored for both sectors.

Whether you’re an Original Equipment Manufacturer (OEM), a powersports enthusiast, or an engineer developing next-gen mobility technologies, here’s what you need to know about EV and hybrid systems in these fields.

Similarities Between Powersports and Automotive Applications

Both powersports and automotive industries have benefited tremendously from adopting electric motors and hybridization. These commonalities drive success across the board:

1. Dual Power Sources

Electric motors and traditional internal combustion engines (ICE) work together to enhance efficiency and performance. For hybrids, ICE most often serves as the primary power source, while the electric motor handles moment-to-moment power bursts and enhances fuel savings. Plug-in hybrid electric vehicles have large enough batteries to run for extended distances with electric propulsion exclusively.

2. Regenerative Braking

Regenerative braking systems are a game changer. They capture energy lost during braking and recycle it to recharge the batteries. This feature reduces energy waste and maximizes the range across EVs, HEVs, and high-performance powersport vehicles.

3. Battery Management Systems (BMS)

A sophisticated BMS is non-negotiable in both sectors to monitor battery health, balance charge cycles, and prevent overheating. Whether you’re running an EV sedan on the freeway or a UTV through rocky trails, a robust BMS keeps things safe and efficient.

While these shared technologies point to a growing synergy in electrification, it’s their differences that make them stand apart.

Differences in Use Cases

The operational contexts of powersports vehicles like UTVs and automotive vehicles couldn’t be more different.

Powersports Applications

- High Torque, Immediate Response

UTVs require instant torque delivery for navigating rugged terrains, hauling loads, or taking on steep climbs. This on-demand power is critical for off-road performance.

- Extreme Conditions

Powersport vehicles are constantly exposed to extreme weather, harsh terrains, dust, and vibrations. Their systems must withstand conditions that would be outliers in automotive settings.

- Recreational and Utility Use

UTVs tackle both work and play—from farmyard duties to thrill-seeking adventures—putting versatility at the forefront of design priorities.

Automotive Applications

- Smooth and Efficient On-Road Use

Sedans, SUVs, and trucks are built for comfort and fuel economy over predictable road terrains. Sustained range and passenger experience take precedence over raw torque.

- High-Speed Optimization

Automotive EVs prioritize aerodynamic performance and steady energy output, ensuring efficiency even at higher speeds.

- Consistent Environment

Unlike powersports, most automotive vehicles operate within controlled conditions, which reduces design challenges like impact resistance or vibration damping.

System Design Considerations

Designing an EV or hybrid system for powersports or automotive applications involves tailoring every component to its intended use case.

Battery Requirements

Powersports Vehicles

- High Discharge Rates

UTVs need batteries capable of rapid, consistent energy release. Quick bursts of torque for challenging trails or moving heavy loads demand extremely responsive power systems.

- Resilience to Voltage Drops

Powersport batteries are engineered to release energy rapidly without causing debilitating voltage drops—a crucial factor for terrain adaptability.

Automotive Vehicles

- Long-Term Efficiency

Automotive batteries emphasize steady energy usage to sustain long-range travel. While they do require moderate discharge capabilities, automotive systems value optimized energy efficiency over extended periods.

Energy Density vs. Power Density

For EVs and hybrids, both energy density and power density are pivotal, but their importance varies by application.

Energy Density

Energy density refers to how much energy is stored per unit weight or volume.

- Automotive: High energy density ensures long-distance range for passenger vehicles. Sedans and SUVs prioritize maximizing travel distance per charge.

- Powersports: While energy storage is a high priority, powersports vehicles lean more on power density.

Power Density

Power density denotes how quickly stored energy can be extracted and used.

- Powersports: High power density provides the immediate torque essential for rock-crawling or high-speed maneuvering over hills.

- Automotive: Though less vital, having decent power density improves acceleration and overall driving dynamics.

Striking the right balance between energy density and power density is essential for optimizing both performance and range in each domain.

Battery Chemistry

The choice of battery chemistry is a crucial factor that differentiates powersports and automotive applications. Two dominant lithium-ion chemistries have emerged in the EV and HEV markets: NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate).

NMC (Nickel Manganese Cobalt) Batteries

Pros:

- High energy density

- Excellent power output

- Lighter weight

Cons:

- Higher cost

- Thermal management challenges

- Potential safety concerns

LFP (Lithium Iron Phosphate) Batteries

Pros:

- Lower cost

- Longer cycle life

- Better thermal stability and safety

Cons:

- Lower energy density

- Heavier weight

Automotive Battery Chemistry

In the automotive sector, both NMC and LFP chemistries are popular, with the choice often depending on the vehicle’s intended use and price point. High-performance models tend to favor NMC batteries due to their superior energy density and power output, which translate to longer range and better acceleration. On the other hand, more budget-friendly models often opt for LFP batteries, capitalizing on their lower cost and longer lifespan to offer affordable EVs with decent range and performance.

Powersports Battery Chemistry

In contrast, the powersports industry, particularly for UTVs and other high-performance off-road vehicles, leans almost exclusively towards NMC batteries. This preference stems from the sector’s prioritization of lightweight design and pure performance. NMC batteries offer the high energy density and power output necessary for the demanding conditions these vehicles face, such as rapid acceleration, steep climbs, and extended off-road adventures. The lighter weight of NMC batteries also contributes to better overall vehicle agility and handling, which are crucial factors in powersports applications. While the additional cost of NMC batteries might be a concern in the automotive sector, it’s often considered a worthwhile trade-off in powersports for the performance benefits gained. The focus on creating exciting, high-performance vehicles often outweighs the cost considerations that might drive automotive manufacturers towards LFP chemistry.

Battery Pack Durability

- Powersports: Batteries are enclosed in highly durable casings with advanced thermal and water protection systems.

- Automotive: Enclosures focus more on safety in everyday collisions and spatial efficiency in the vehicle chassis.

Motors

Good EV and HEV engineers know that using the right electric motor and understanding the relationship between the motor and batteries can be the difference between a vehicle’s roaring success and a performance flop.

- Powersports: High-torque motors to handle immediate off-road demands.

- Automotive: Efficient motors tuned for minimal energy wastage during long-distance commutes.

Controllers

The controller manages the EV or HEV system overall like motor speed, torque, power delivery, and safety monitoring. It’s a key component for both Powersports and Automotive but it prioritizes different things for each.

- Powersports: Controllers prioritize rapid responsiveness, allowing vehicles to adapt instantly to terrain changes, technical driving and aggressive acceleration.

- Automotive: These systems focus on smooth power delivery and maximizing battery performance over time.

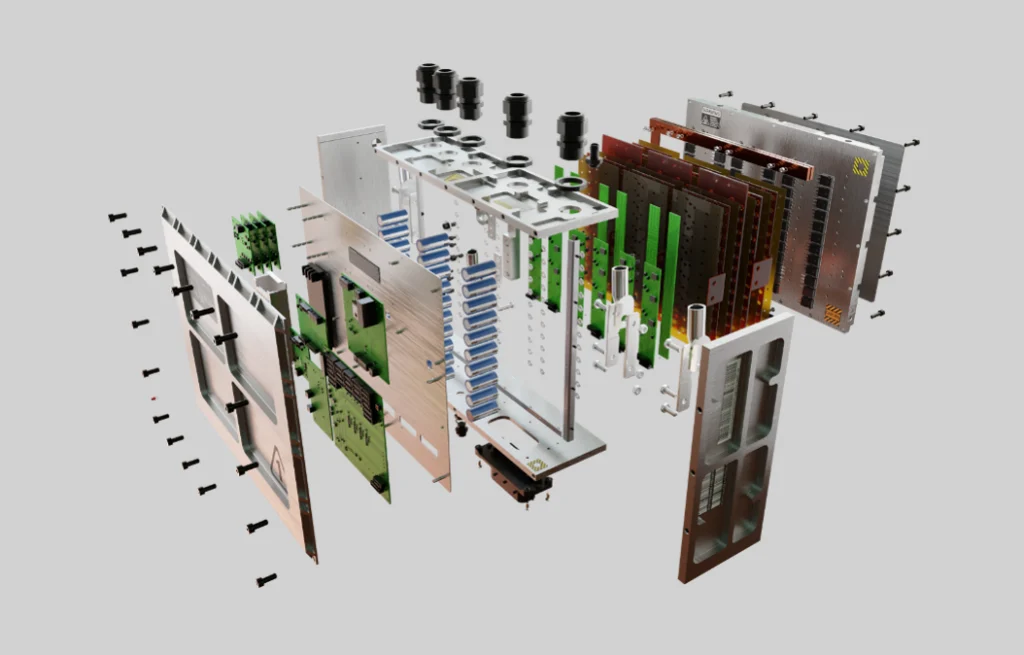

Power Electronics and Packing

A ruggedized design for power electronics ensures that UTVs can survive muddy, dusty, and wet environments. Automotive electronics can afford to focus more on compact and efficient designs for aesthetic integration into smooth car builds.

Designing for the Future of Mobility

While EV and hybrid systems share core principles, understanding where they intersect—and where they diverge—is pivotal for manufacturers. OEMs and engineers need to factor in specific use cases to tailor designs effectively, ensuring safe, efficient, and high-performing products.

For powersports enthusiasts seeking pure adrenaline or businesses looking for hard-working vehicle solutions, hybrid and EV UTVs continue to raise the bar. Meanwhile, the automotive industry powers forward, delivering increasingly refined and efficient driving experiences to growing consumer markets.

Accelerate Innovation with Expertise

The rise of electrified mobility requires collaboration, innovation, and expertise. For OEMs and brands looking to explore cutting-edge EV and hybrid solutions, there’s never been a more critical time to collaborate with skilled partners and engineers who think fast, ask the right questions, and drive solutions.

Want to stay ahead of the electrification curve? Subscribe to our newsletter for exclusive updates and expert insights on the next evolution in EV and hybrid mobility.